You must know the six acceptance techniques of laminate flooring

June 24, 2025

Laminate flooring problems are endless? It may be that these 6 points were not done well…

For laminate flooring paving, many people choose laminate flooring because it is resistant to pollution, scratches, and easy to take care of… It is easy to maintain, but some people find that the quality of the floor is clear, and they usually pay attention to maintenance. Why? Still have various problems? In fact, most of the reasons come from the substandard paving quality, which greatly reduces the life of the floor. Therefore, you must know the six acceptance techniques of laminate flooring.

1. Visual inspection

The surface of the newly installed laminate flooring should be clean, free of water stains, stains, and no corners, cracks, scratches, etc. on the floor.

2. Firmness check

Stomping hard with your foot to see if there is any abnormal noise, especially around the wall, and observe for softness and dusting. In addition, there must be an aluminum buckle at the joint between the floor and the door stone, and quickly tap it with the sole to see if it becomes loose.

3: flatness inspection

To check the flatness, you need to use professional tools-a 2m ruler or a string. At least two locations should be found in a space for inspection. Take the maximum value. The result is qualified if the deviation between the floors within 2m is less than or equal to 3mm.

4. Splicing height difference check

The splicing height difference is the relative height deviation of the gap between two adjacent floors. The inspection tool is a feeler gauge with a precision of 0.02mm and a steel ruler. The allowable error of the splicing height difference of the laminate floor is less than or equal to 0.15mm.

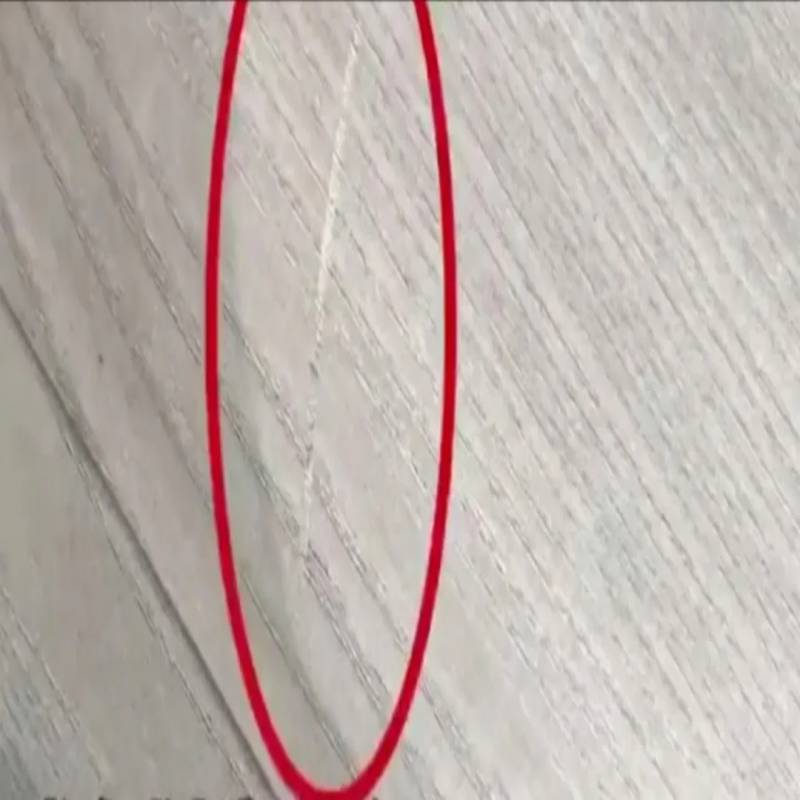

5. Splicing and seam inspection

The splicing gap of the laminate flooring should not be greater than 0.2mm. If the gap is too large during installation, it will not only affect the appearance, but also easily hide dirt. During acceptance, a feeler gauge with an accuracy of 0.02mm should be inserted into the seam for inspection. If there is no professional tool, you can use the back of a utility knife to insert into the seam of the floor. It means that the seam is too large.

6.Check the surrounding expansion joints

There should be an expansion joint of 8-12mm between the flooring, the wall and the ground fixture, otherwise it will be arched due to thermal expansion and contraction. Use a steel ruler with an accuracy of 0.5mm during inspection.

The above are the six points for acceptance of laminate flooring installation. If you want to install laminate flooring, you must study carefully.

Excellent flooring design team, with experienced flooring sales team, 24 hours for customers around the world to provide floor answering service.

Email:ventas@labsunwood.com

+86 17753100577

+86 17753100577 manager@beflooring.com

manager@beflooring.com